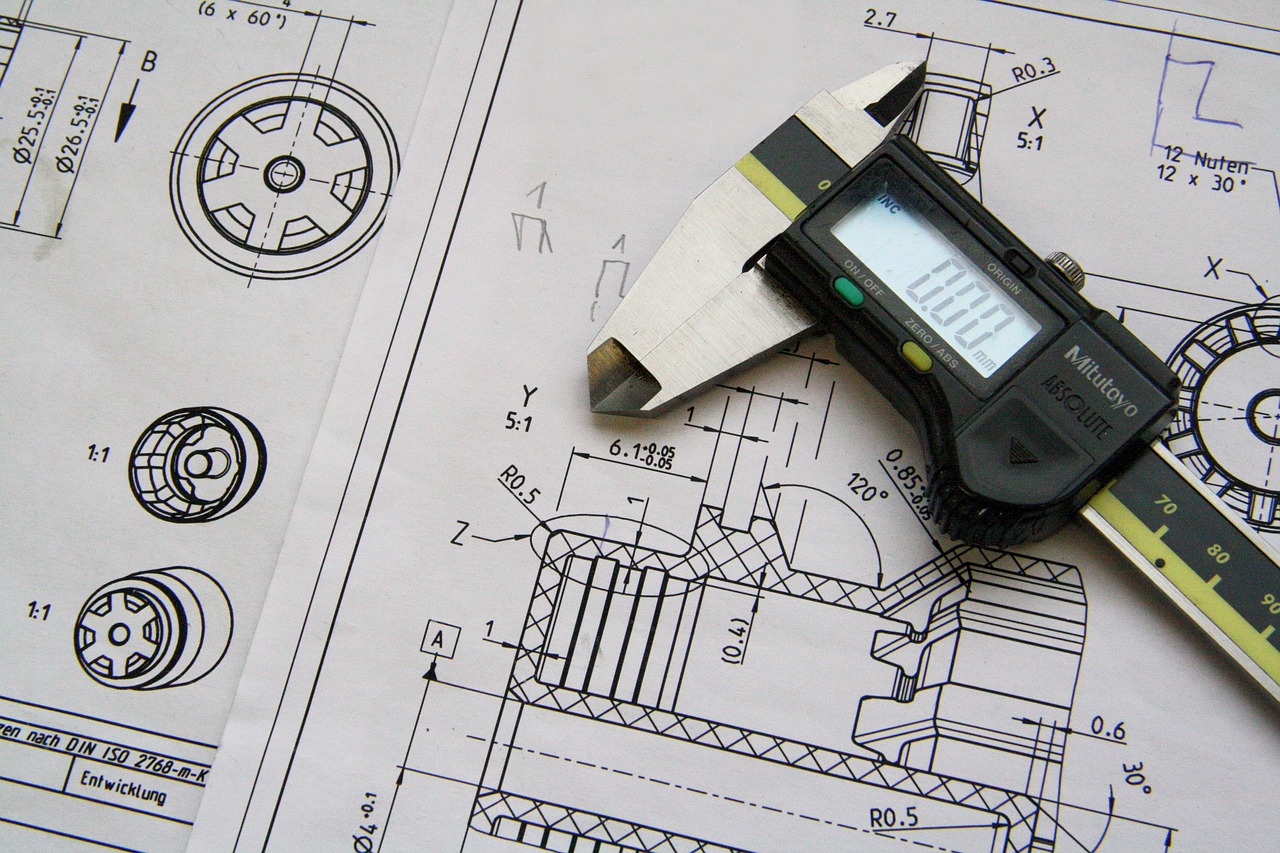

Product design & support

Our product design and engineering services includes 3D CAD modelling, reverse engineering, product detailing for plastics and metals, design for manufacturing studies (DFM/DFMEA), product re-engineering, value engineering to study alternate manufacturing methods, cost optimization. Furthermore, the team at GAK Enterprises Limited has a great deal of collective experience in several domains, which enables us to provide consulting services in almost any field. We have consulted on a wide range of projects to both Governmental and Non-Governmental organizations. Our vision is to help the start-ups and organizations with limited resources to build revolutionary products with the help of our experience and resources fostering the growth of both organizations.

- Seating Systems

- Automotive interiors/ exteriors

- Automotive BIW

- Medical products

- Machine Design

- Static, Dynamic & Fatigue Testing

- Multi-physics

- Computational Fluid Dynamics

- Value Engineering

- Vehicle E/E Engineering

- E/E Systems Engineering

- E/E Verification Validation

- R & D in Electrical and Electronics

- Robotics

- Indigenous Products

- Firmware & Software

- Strong Design capability for practical solutions and designed for manufacturability.

- Simultaneous engineered BIW design.

- Lightweight BIW solutions.

- Design capabilities – Wiring harnesses, connectors, moulded plastic components, injection moulding tools, rear vision systems and complete module designing and strong benchmarking experience.

- Safer BIW structures to meet the requirements

- Instrument Panel

- Centre Console

- Door Trims (Soft & Hard skin)

- Garnish Trims

- Luggage compartment

- Impact beam

- Seating

- Bumper & Front end module

- Body side Cladding & Garnish

- Rocker Moulding

- Roof Rail System

- Exterior Grill

- Head light interface

- Benchmarking

- Tolerance Stack-up Analysis

- Flush-Gap study

- Homologation & Localization Support

- Manufacturing & Assembly Feasibility

- Package development

- Static & Dynamic clearance studies

- Interface development

- Sub-system interface development

- DFA evaluation

- Component & system tolerance study

- Reverse Engineering

- Support styling & studio requirements

- Support panel for feasibility

- Assembly fitment/Removal study

- Static/Dynamic clearance

- Forming feasibility material

- Material selection based on the joint & tolerance

- Component breakdown

- Incorporate styling lines

- Develop master sections

- Accommodate aggregate

- Positioning to ensure function

- Ergonomics study

- Process development based on section requirement

- Support styling & studio requirements

- Support panel for feasibility

- Assembly fitment/Removal study

- Static/Dynamic clearance